La fabricación de tanques superiores es un desarrollo meticuloso que requiere experiencia en soldadura y conocimientos expertos en estructuras metálicas. En Estructuramex, cada tanque elevado se fabrica con los más altos estándares de calidad, utilizando técnicas destacadas y materiales de primera calidad. En Estructuramex, sabemos que la fabricación de tanques elevados es un proceso crucial en la ingeniería de construcciones metálicas, en especial en el ámbito de la distribución y almacenaje de agua. Los tanques elevados ofrecen una sucesión de virtudes significativas que los convierten en una opción preferida en muchas apps. Cuando se trata de fabricación de tanques elevados, la personalización juega un papel vital para agradar las pretensiones específicas de cada proyecto.

Con mucho más de una década de experiencia en el campo, en Estructuramex hemos perfeccionado la técnica de crear resoluciones conforme se amoldan de manera perfecta a los requisitos de sus clientes. En nuestro proceso de construcción reservatorio de agua tipo taça usado tanques elevados, no solo nos encargamos de la fabricación desde el princípio del tanque, sino asimismo su instalación y puesta en funcionamiento.

Con mucho más de una década de experiencia en el campo, en Estructuramex hemos perfeccionado la técnica de crear resoluciones conforme se amoldan de manera perfecta a los requisitos de sus clientes. En nuestro proceso de construcción reservatorio de agua tipo taça usado tanques elevados, no solo nos encargamos de la fabricación desde el princípio del tanque, sino asimismo su instalación y puesta en funcionamiento. This state of the art facility consists of (6) 2000 MT silos with a total operating storage capability of eight,000 cubic meters. Unique to this facility is the assist for each rail and truck material receiving. Tank Connection was chosen for this bolted RTP (rolled, tapered panel) building tank that has a capacity of over one hundred seventy,000 gallons for fire safety water usage in Texas. Tank Connection’s bolted RTP (Rolled, Tapered, Panel) silos feature dependable product flow, and remarkable coating toughness. Bolted RTP designs present the freedom of various configuration and accent options.

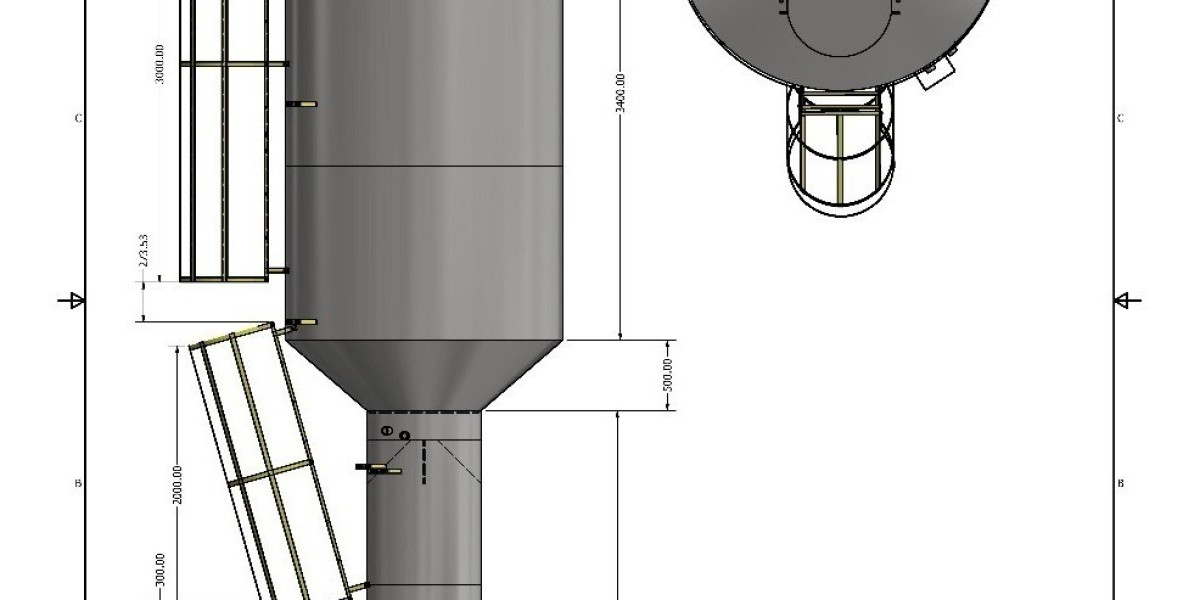

This state of the art facility consists of (6) 2000 MT silos with a total operating storage capability of eight,000 cubic meters. Unique to this facility is the assist for each rail and truck material receiving. Tank Connection was chosen for this bolted RTP (rolled, tapered panel) building tank that has a capacity of over one hundred seventy,000 gallons for fire safety water usage in Texas. Tank Connection’s bolted RTP (Rolled, Tapered, Panel) silos feature dependable product flow, and remarkable coating toughness. Bolted RTP designs present the freedom of various configuration and accent options.Request for Spheroid Elevated Tank Drawings/Specifications

The metal tank is constructed at ground degree for greater safety and control of tolerances. Contact us to study more about set up companies, raingarden installation and custom tanks. The STI/SPFA Product Awards acknowledge steel building product achievements that exemplify the steel tank industry. The rafter ring was designed to set inside 1 inch of the grating stage per customer request. In addition, the nozzles have been designed to protrude through the platforms to offer the shopper entry to bolt the piping to the flanges. This was a particular request by our buyer, and so they had been very happy with the result.

Standards & Specifications

Towers should provide a minimal of 20 psi of water stress to customers inside the distribution system at all times, though commonplace strain is much higher—typically between 60 and 70 psi. The top of the elevated tank should be adequate to make sure a constant minimal stress to all factors within the distribution area. Maintenance durations for glass-fused-to-steel tanks are typically 15 to twenty years and require minimal work compared to repeatedly portray a subject welded tank. This saves hundreds of 1000's of dollars over the service life of the product. Design requirements are essential but ought to be put into perspective as they relate to good, general design practices. It is sound, experienced engineering judgment at the side of requirements, expertise, R&D, testing, and/or empirical results that make up the nice design of any engineered product, together with water storage tanks.

Multi-Column Elevated Strorage Tanks

If your project includes a single steel water storage tank or an built-in municipal water storage system, no one provides extra services and artistic options than Tank Connection. From the quote stage through order process, drawing approval, materials fabrication, and area set up, Tank Connection will present streamlined processing and Golden Rule customer service. Our pedestal design utilizes the best quality jump-form concrete pedestal development. Additionally, our pedestal design can embody a quantity of storage ranges similar to the designs we routinely provide within the power industry. Tank Connection's RTP (rolled, clique na seguinte página web tapered panel) tank design is out there with our prime efficiency coating system for potable water storage, LIQ Fusion 8000 FBE™. The tank cover is out there in the same building as the tank or with an aluminum geodesic dome.

In this case only areas with the most unfavorable potential (anodes) are destroyed. While the areas of surface with the more positive potential (cathodes) do not present destruction. The completed painted surface ought to have equal layer thickness without paint dips and other defects. Mechanical cleaning and degreasing is completed for the entire exterior floor of the tank. We deal with the allowing and coordinate our work with a third-party SSPC/NACE coatings inspector and our customer Safety Team. It’s noteworthy that concrete tanks made in accordance with AWWA D110 and D115 are permitted to leak.

We are a tried and true industrial tank sandblasting and painting contractors. Servicing nationwide.

We are also conscious of every client’s price range, and our in depth experience in this trade permits us to search out methods to maximise the use of different supplies. If a side of the job isn’t needed, we’ll provide you with full disclosure, so that you don’t waste your resources. Due to our advanced training, we may even suggest alternative options that may suit your budget. We use our trade experience, and we apply transparency, integrity and honesty in all our dealings with different shoppers. Apart from our tank lining and coating services, we additionally present a comprehensive suite of economic and industrial portray companies.

The same NSF 61 epoxy linings used to protect consuming water tank interiors are additionally used to guard salt water steel pilings, for example, from corrosion, in winter, summer time, and any climate in-between. Since they have been around for a while, latex or water-based paints are incessantly the product of selection for many. These paints are made from acrylic, vinyl, or composite supplies based mostly on rubber. The short drying period of water-based paints is considered one of their most well-liked advantages. Before applying primer or paint, be positive that the floor of the tank is completely dry. This might involve leaving the tank to air dry for a time period, or you may want to use towels or a blower to speed up the drying process. It is necessary that no moisture stays on the floor, as this will have an effect on the adhesion of the new paint.

Finishing Work

Options for rust and resistance to moisture should also be taken into consideration. Any steel surface regularly being uncovered to moisture needs to be painted with rust-resistant paint. Finally, once the primer is dry and the surface is easy and prepared, you'll find a way to proceed to the painting stage, following the producer's directions for the paint you have chosen. Remember that correct preparation, including priming, is key to achieving a clean and long-lasting finish on your metallic water tank exterior. When selecting the topcoat, think about the particular kind of metal and the setting will in all probability be exposed to. For non-ferrous metals, waterborne enamels are a good selection, while for ferrous metals, alkyd enamels are usually beneficial. If you would possibly be portray a metallic water tank exterior, go for a paint that is particularly designed for exterior use and might stand up to weather conditions and moisture.

Services

Electro-chemical storage tank corrosion protection is the only effective method in opposition to probably the most native forms of metal corrosion (pitting and gap corrosion, contact corrosion, intergranular corrosion and cracking). Home Works Painting is a business that handles the painting needs of residential and business shoppers in Ashburn and the encircling areas. Founder and president Mike Katounas started the business in 2005 with one van and two guys. Katounas and his team attend ongoing training to keep up to date with the trade's latest practices.

How to Select Industrial Coatings for Steel Water Tank Exteriors