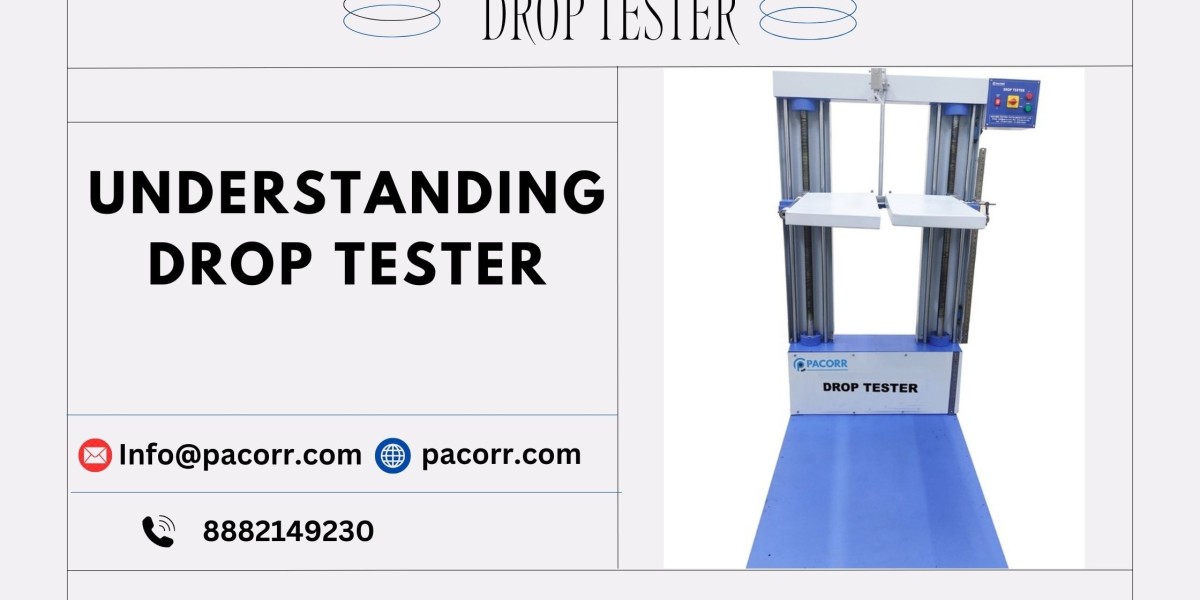

At Pacorr.com, we specialize in providing high-quality, precision-engineered drop testers designed to meet the testing needs of a wide range of industries, from electronics and packaging to automotive and consumer goods. Here, we’ll delve into the importance of Drop Tester, the technology behind them, and how Pacorr can help your business ensure product reliability and enhance customer satisfaction.

What is Drop Testing?

Drop testing is a type of mechanical testing that involves subjecting a product or package to repeated drops from a specified height to observe its reaction. This test can reveal potential weaknesses in the design, materials, or assembly of the product, helping manufacturers make necessary adjustments before products reach the market. The test typically measures factors such as breakage, structural integrity, and resilience, ensuring that the product can endure various forms of physical stress.

Why is Drop Testing Important?

- Protecting Product Integrity: Drop Testing allows manufacturers to ensure that products can survive unexpected drops and impacts. This is especially important for fragile items, such as electronics or glassware, which may be more prone to damage.

- Reducing Returns and Complaints: One of the primary reasons for product returns and negative reviews is product failure during transit or handling. Drop testing helps identify and mitigate these issues beforehand, improving customer satisfaction and reducing financial losses.

- Meeting Industry Standards: Different industries have specific standards for product durability and resilience, such as ISTA, ASTM, and ISO. Drop testing helps companies comply with these industry standards, proving that products meet the necessary requirements.

- Sustainability and Waste Reduction: With increasing focus on sustainability, drop testing ensures that products are durable enough to avoid early failure. By making sure products don’t break easily, manufacturers can reduce waste and encourage longer product lifecycles.

Types of Drop Tests Conducted in Industries

There are various types of drop tests that can be tailored to the specific needs of an industry or product. Here are some common types:

- Free-Fall Drop Testing: In free-fall testing, the product is dropped without any external support, simulating the natural fall it may experience during handling or transport.

- Edge, Corner, and Face Drop Testing: Products can be dropped on specific parts like edges, corners, or flat surfaces to identify vulnerabilities and weak points.

- Repeated Drop Testing: This test involves multiple drops from a specific height to gauge the durability of products that might undergo frequent handling.

- Inclined Impact Testing: Used mainly for packaging, inclined impact testing assesses how packages or large items react to impacts when sliding down a plane.

Pacorr offers versatile drop testing equipment capable of conducting these and other Drop Tester Price to cater to the unique requirements of different products and industries.

How Drop Testers Work: Understanding the Technology

A typical drop tester machine includes components that allow for controlled and precise dropping of the product. Here are the primary elements:

- Platform and Clamps: Drop testers use clamps or platforms to hold the product in place until it’s released for testing. These mechanisms ensure that the product is dropped from the exact height and in the specified orientation.

- Adjustable Heights and Angles: Modern drop testers like those from Pacorr allow for height adjustment and angle customization, enabling tests to simulate real-life conditions.

- Release Mechanism: Drop testers feature sophisticated release mechanisms to avoid interference in the product’s natural free fall, ensuring the test’s accuracy.

- Impact Surface: Drop testers are equipped with impact surfaces that can be adjusted or customized based on the type of drop test required.

- Data Collection Sensors: Some advanced drop testers may be equipped with sensors to collect data on the impact force, which can provide valuable insights for analysis.

Features of Pacorr’s Drop Tester Machines

At Pacorr.com, our Drop Impact Tester machines are designed with a focus on durability, accuracy, and ease of use. Here are some standout features:

- Precision Height Adjustment: Our drop testers allow for precise height settings to accommodate various drop heights required in industrial testing.

- User-Friendly Interface: Equipped with an intuitive interface, our drop testers make it easy to conduct tests and analyze results efficiently.

- Robust Build Quality: Made from high-quality materials, Pacorr’s drop testers are designed to withstand repeated use, making them a long-term investment for quality control labs.

- Compliance with Industry Standards: Pacorr’s machines comply with international testing standards, ensuring that your products meet regulatory requirements.

- Customizable Test Settings: Our drop testers allow for customizable test settings, from drop angles to impact surfaces, providing flexibility to simulate different real-world scenarios.

Industries that Benefit from Drop Testing

- Electronics: Electronics are sensitive to shock and impact, and drop testing ensures that devices such as phones, tablets, and laptops can withstand drops during daily usage.

- Packaging: Packaging materials, especially for fragile items, undergo drop testing to verify that they can protect products during transit.

- Automotive Parts: Automotive parts and components are tested to ensure they can handle impacts without breaking, contributing to overall vehicle safety.

- Consumer Goods: From toys to furniture, consumer goods are tested for durability to ensure longevity and reliability in everyday use.

- Medical Devices: For medical devices that require safe and sterile handling, drop testing ensures they maintain their integrity even in challenging environments.

How to Choose the Right Drop Tester for Your Business

Choosing the correct Drop Tester depends on several factors, including the type of products you manufacture, testing standards, and budget. Here are some tips for selecting the best drop tester:

- Consider Your Industry’s Standards: Make sure the drop tester complies with the specific testing standards relevant to your industry.

- Identify Testing Requirements: Determine the types of drop tests you need to conduct, such as free-fall or inclined impact. Choose a drop tester that supports these requirements.

- Check for Adjustable Features: A drop tester with customizable settings, such as adjustable drop height and angles, is ideal for versatile testing needs.

- Look for Durability and Ease of Use: Drop testers are long-term investments, so it’s crucial to choose a model that’s both durable and easy to operate.

Pacorr provides expert guidance to help you find the right drop tester for your specific needs. Our customer service team is available to assist you in evaluating options and making an informed decision.

Why Choose Pacorr for Your Drop Testing Needs?

At Pacorr.com, we prioritize quality, precision, and customer satisfaction. Our range of drop testers is engineered to deliver reliable results that can help enhance your product’s durability and safety. Here’s what sets us apart:

- Expertise and Support: With years of experience in the industry, we provide exceptional customer support, helping you understand and implement drop testing effectively.

- High-Quality Machines: Pacorr’s drop testers are built with top-quality materials and precise engineering, ensuring accurate and dependable testing.

- Competitive Pricing: We offer competitive pricing on all our products, providing value for money without compromising on quality.

- Compliance and Certification: Pacorr’s machines adhere to globally recognized testing standards, ensuring you meet industry regulations and pass quality audits.

Conclusion

Incorporating drop testing into your quality assurance process can have far-reaching benefits, from minimizing product returns to bolstering customer satisfaction and meeting industry standards. Pacorr’s drop testers offer a robust solution for businesses looking to conduct precise and reliable drop tests on their products. Whether you’re in electronics, automotive, packaging, or consumer goods, Pacorr’s drop testing solutions are designed to meet the specific needs of your industry.

For more information on Pacorr’s drop testers or to speak with our team of experts, visit Pacorr.com today. Our team is ready to help you find the best testing solutions to enhance the quality and durability of your products, ensuring they reach your customers in perfect condition.

FAQs

1. What heights are typically used in drop testing?

The drop height depends on the product and industry standards, ranging from as low as a few centimeters to over a meter. For consumer electronics, a standard height is around 1.2 meters, simulating a typical drop.

2. Can drop testers be used for both packaged and unpackaged products?

Yes, drop testers are versatile and can test both packaged and unpackaged products to assess the durability of both the product and its packaging.

3. How often should drop testing be conducted?

Drop testing frequency varies. For new product designs, it should be a regular part of the development process. It’s also recommended to conduct periodic tests on existing products to ensure consistency.

4. Is it possible to customize drop testers for specific testing needs?

At Pacorr, we offer customization options to cater to specific drop heights, angles, and impact requirements based on your product's unique testing needs.

Contact Us:

- Email: Info@pacorr.com

- Phone: 8882149230

- Visit our website at www.pacorr.com for more details on our testing instruments.