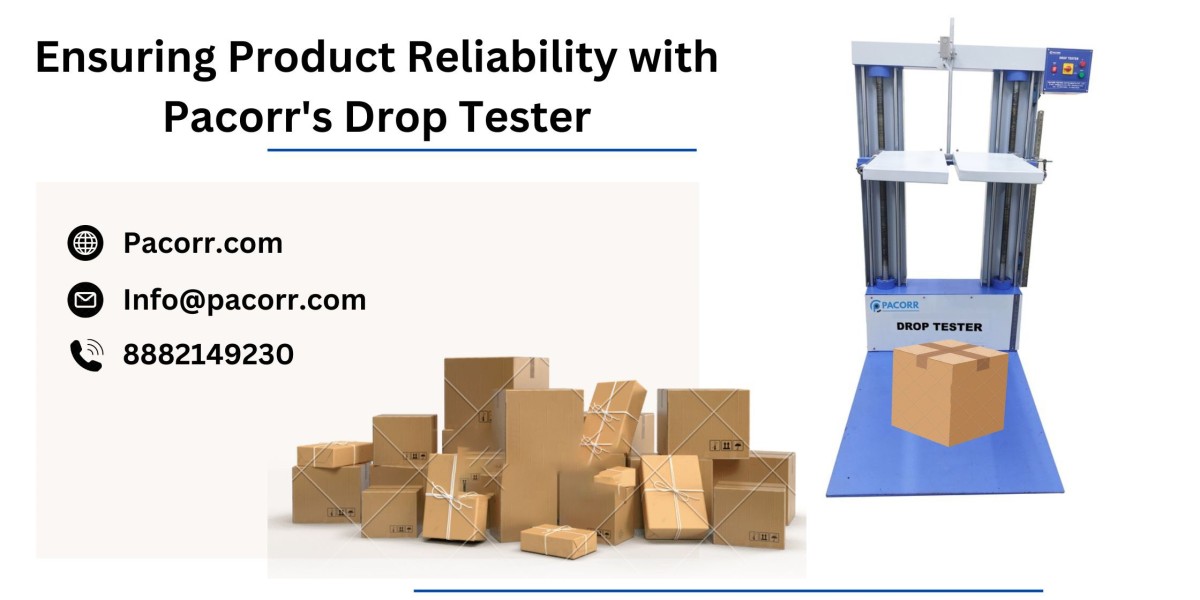

What is a Drop Tester?

A Drop Tester is an essential testing instrument used to assess the impact resistance of packaging by simulating free-fall drops that packages might experience during handling, transportation, or accidental falls. The device replicates the real-world conditions a package might encounter, ensuring that the packaging can withstand such impacts without compromising the product inside.

Key Features of Pacorr's Drop Tester

Pacorr offers a state-of-the-art Drop Testing designed to meet the rigorous demands of modern packaging testing. Some of the key features include:

- Adjustable Drop Height: The tester allows users to set various drop heights, ensuring comprehensive testing for different packaging sizes and weights.

- Precision Control: With advanced control mechanisms, the Drop Tester ensures accurate and repeatable drop tests, providing reliable data for packaging evaluation.

- Versatile Testing: The machine is capable of testing various packaging types, from corrugated boxes to plastic containers, making it suitable for a wide range of industries.

- Durable Construction: Built to last, the Drop Tester is constructed with high-quality materials, ensuring consistent performance over time.

Why Is Drop Testing Essential?

- Ensures Product Safety: By simulating the drop conditions a package might encounter, the Drop Tester helps identify potential weak points in the packaging. This ensures that the product inside remains safe and intact, even under rough handling.

- Compliance with Standards: Many industries have strict regulations regarding packaging durability. A Drop Tester Price helps manufacturers meet these standards, ensuring their products are compliant with industry norms.

- Cost Efficiency: Identifying and rectifying packaging weaknesses early in the production process can save companies significant costs related to product returns, damages, and customer dissatisfaction.

- Enhances Brand Reputation: Delivering products in perfect condition enhances customer satisfaction and strengthens brand reputation. Investing in robust packaging testing like drop testing shows a commitment to quality.

How to Use Pacorr's Drop Tester

Using Pacorr's Drop Impact Tester is straightforward, with a user-friendly interface designed for efficiency. The package is placed on the testing platform, and the desired drop height is selected. Once the test begins, the package is released, and the impact is observed. The results are then analyzed to determine the packaging's ability to protect its contents.

Applications of Drop Tester

The Drop Tester is versatile and finds application in various industries, including:

- Electronics: Ensuring that delicate components survive transit.

- Food and Beverage: Testing packaging for spill prevention and durability.

- Pharmaceuticals: Ensuring the integrity of sensitive products.

- Consumer Goods: Testing everyday items to ensure they reach consumers without damage.

Conclusion

At Pacorr, we understand the importance of reliable packaging in protecting your products. Our Drop Tester is designed to provide precise, repeatable testing that ensures your packaging meets the highest standards of durability and safety. Invest in Pacorr's Drop Tester today to safeguard your products and your brand reputation.

For more information, visit our website pacorr.com or contact our customer support team.