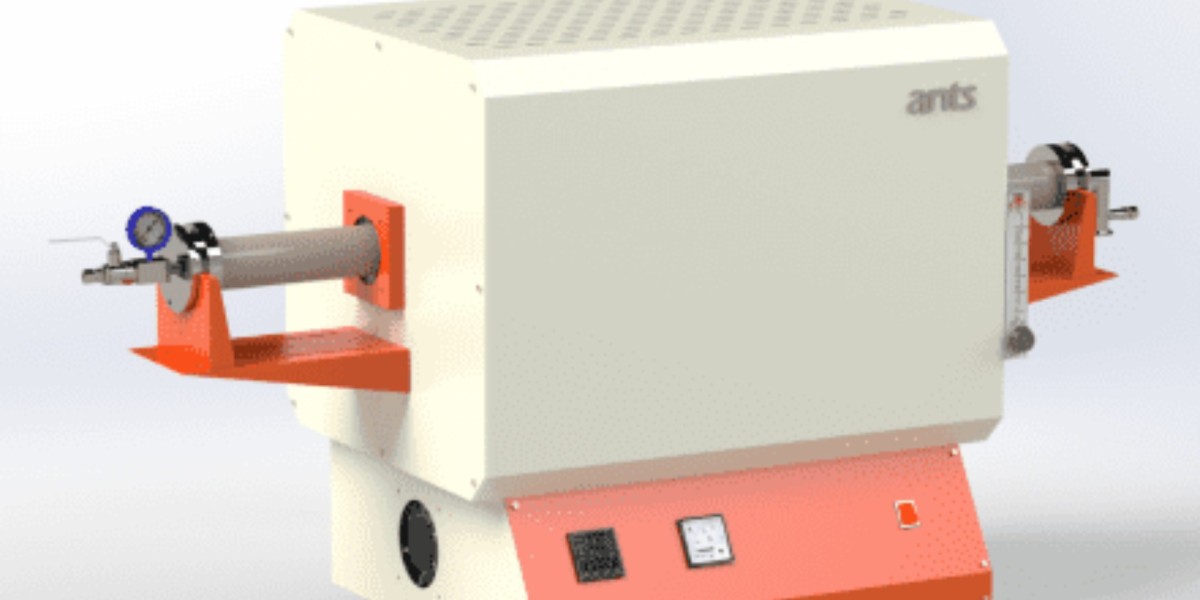

The selection of themost suitable tube furnaceto your laboratory is essential to ensure accurate temperatures, superior research outcomes, as well as operating efficiency.With different sizes, types and configurations to choose from it is essential to know how to use them and then match them to the task that you have to complete.This article will offer an extensive guideline on the factors to take into consideration when selecting the best tube furnace for your requirements.

1.Understand Your Application Requirements

Different laboratories have their own unique functions and each requires particular features of tubes furnaces.Are you performingthermal treatment such as calcination, annealing, or both?Understanding the primary purpose will help narrow down the requirements needed, including:

- Operational temperature range

- The type of gas in question (inert and reactive gas)

- Size of the sample and volume

- Heating uniformity is a must

Forfragile materialssuch as ceramics and advanced composites, accurate temperature control is essential for temperature control, whileroutine tasksmay only require basic temperature control.Make sure to ensure that the capabilities of the furnace with the work your lab does to avoid inefficiencies during operation.

2. Choose the Right Temperature Range and Accuracy

Thetemperature rangeof tube furnaces differs in some models, offering the range ofthe ambient temperature to 1200 degrees Celsiusor more, whereas high-temperature models can have a temperature range of1600degC or more.A precise temperature control is crucial for any experiment that requires:

- Sintering and the synthesis of material

- Thermal decomposition processes

- Metals are reduced or oxidized.

Check yourtemperatures uniformitythroughout the heat zone.If your process requires consistent heat distribution, choose multi-zone tube furnaces that guarantees temperature uniformity.Also, select one that comes withdigital temperature controllersto make precise adjustments.

3. Consider Furnace Tube Material and Diameter

The materials and the size in the size of the furnace tubes play a significant aspect in achieving desired outcomes.The most common tube materials are:

- Quartzis suitable for high-purity applications, and is resistant to radiation from infrared.

- AluminaAlumina is perfect forapplications requiring high-temperatureand resistance to chemical.

- Stainless Steel: It is used to work withgaseous reactive substancesas well as at low temperatures.

Thesize of the tubeis determined by the size of the sample as well as experimental requirements.A tube with a larger diameter will allow larger sample volumes, but can impactthe efficiency of heating.Choose a tube that can accommodate the size of your sample while retaining the best heating properties.

4. Decide Between Horizontal or Vertical Orientation

Tube furnaces are available invertical and horizontal configurationsand are suited for various uses.

- Horizontal Tube FurnacesPerfect to use forconstant heatprocesses, like metal oxidation or material sintering.

- Vertical Tube Furnacesare better suited to experiments in which gravity plays a key role, for examplethe growth of crystalsas well asthe diffusion of heat.

Select the one that is most compatible with the workflow and configuration of your lab.Some models that are more advanced also providemechanism for tiltingto maximize the advantages from both directions.

5. Assess Atmosphere Control Capabilities

A variety of research projects requirecontrolled environmentsto obtain specific results.Tube furnaces typically allow for different atmospheric conditions, including:

- Inert (argon, nitrogen): To prevent oxidation during high-temperature processes.

- Reactive (oxygen hydrogen): For processes such as reduction and oxidation.

- Vacuumis used to remove contaminants and create ultra-pure environments.

Choose a furnace withsealed tube tubes that are gas sealedandvacuum pumpfor experiments that require an inert or vacuum atmosphere.This can improve the results of your experiments and will prevent unwanted reactions.

6. Evaluate the Heating Elements

Heating elements directly influence your furnace'smaximum temperature and its longevity.Common heating elements include:

- Kanthal (FeCrAl): Durable and cost-effective, suited for temperatures of up to1300degC..

- Silicon Carbide (SiC)Best suited for temperatures ranging from1400degC to 1600degC..

- Molybdenum Disilicide (MoSi2): Capable of handling temperaturesas high as 1800Cfor applications with high temperatures.

Make sure that the material used for heating corresponds to the temperature of operation in conjunction with the selected tube for your furnace.

7. Prioritize Safety Features and Compliance

Security is essential when working in a laboratory.Make sure the furnace you choose is compliant withinternationally recognized safety guidelines(likeCE or ISO certifications) and comes with options like:

- Protection against over-temperatureto avoid overheating.

- Automated shut-off mechanismswhen malfunctions occur.

- Protection from heat lossto reduce heat loss and ensure security for users.

Also, think aboutthe ergonomic designand furnaces that havecooling-touch surfacesfor a safer handling operations.

8. Choose the Right Control System and Automation Options

Modern tube furnaces providesophisticated control systemsto automatize processes and guarantee precise temperature control.Consider features such as:

- PID controllers that have different heating programs.

- Ethernet as well as USB connectivityto record data

- The ability to monitor remotelyto manage the furnace from afar

Automation options can improve efficiency and decrease human error, thereby making your lab operations more efficient.

9. Evaluate Energy Efficiency and Maintenance Needs

Energy efficient tube furnaces can drastically reduce operating costs over the long-term.You should look for:

- Insulation with low thermal massto limit heat loss.

- Heating elements that are energy efficientthat produce high power without consuming a lot of energy.

Additionally, take into consideration yourneed for regular maintenance.Furnace withparts that are modularare simpler to maintain, while appliances equipped withself-diagnostic technologywill alert users to possible issues earlier, thus reducing the amount of downtime.

10. Set Your Budget and Explore Customization Options

In the end, budget is an important factor in the process of selecting a furnace.Tube furnaces with high-end features come with sophisticated features, but they might not be required in every situation.Check out different models to find the ideal combination ofprice and performance.

Certain manufacturers also providetube furnacesthat are specifically tailored to research requirements.If your laboratory has special specifications, it might be worth looking intopossibilities for customizationto achieve the best possible outcomes.

Conclusion: Finding the Ideal Tube Furnace for Your Lab

The selection of the ideal tube furnace requires careful consideration of a variety of factors that includethe temperature range, tube materials control systems, and needs for the atmosphere.When you align these components to your laboratory's requirements and requirements, you will be able to guarantee optimal performance, safety, as well as efficiency for every experiment.Consider comparing various models and talk to experts for an informed choice that will benefit your research for many years to come.